Iplate enganyangekiyo kukugqalwa njengengxubevange enobunzima obuphakathi obuphezulu be tungsten, kwaye phambi kokufakwa, inokuzikhusela izixhobo ekungqubaneni. Esi sithuba siza kwabelana ngendima ebalulekileyo yeplate enganyangekiyo kule zilwanyana zikhulu. Ngaba ufuna ukwazi okungakumbi ngeli nqaku? Nceda uzive ukhululekile ukusityelela kwi-china alloy ekhethekileyo. Ufanele uqonde iintlobo ezahlukeneyo ze-WRP nendlela yokuzenza zibonakale kakuhle, 2. Emva kokufunda eli nqaku, uya kuthathwa njengengcali yeplate enganyangekiyo! Iipleyiti Ezingagqitywa Ngokusetyenziswa Kwemizi-mveliso [Inkcazelo Engakumbi]. Iplate yokunxiba inqabile luhlobo lwesinyithi esenziwe ukuba sikwazi ukumelana nokugqwala kakhulu. Ngexesha lomsebenzi wokwakha nowemigodi, kukho uxinzelelo oluninzi koomatshini abanzima. Yaye ngaphandle kwezinto ezomeleleyo, izixhobo ziya konakala ngokukhawuleza, zibeke abasebenzi engozini. Iplate enganyangekiyo kukudleka ingena apha, ngelixa besebenzisa le nto ikhethekileyo, iinjineli zinokwenza izixhobo ezihlala ixesha elide, kwaye banokugcina izixhobo zabo zingagqitywa kaninzi. Isizathu Sokuba Umele Ube Neplate Eyamelana Nokunxiba Kwimishini Enzima. Oomatshini abasebenza nzima basetyenziswa ngokubanzi kumacandelo ahlukeneyo afana nolwakhiwo kunye nokusebenza komhlaba wezolimo. Akunamsebenzi, kodwa ezinye zezinye iindawo zenziwa ngemishini embalwa ekufuneka isebenze ngelixa isomelele kwaye ichanekile kangangoko kunokwenzeka ukuze umsebenzi wenziwe ngokufanelekileyo. Kulapho i-plate yokunxiba inganyangekiyo ingena khona. Abavelisi bafaka ipleyiti enganyangekiyo xa kusetyenziswa oomatshini babo, nto leyo eyenza ukuba bahlale ixesha elide yaye kube lula ukuyinyamekela.

Ngoko, ngumoya yeyiphi ngenxa yokuthi zingaphambili kwiinkcukacha ezilandelayo kuzohamba ukuvula umbhobho? Iindlela eziziziyo lokusebenza kweendlela ezinomsindo ezikhoyo kunye nezindawo eziphakanyiswayo zihluke amakhulu kunye nemikhakathelo emasinyeni akhona okuyisekelwa ngokubanzi kakhulu. Izindawo ezifanele zikwazi ukusuka ngaphandle kokugqibela kungcono lokusebenza ngokuba kungabangako isikhatsi esidingayo. Ukufa kwesithuthi, ngokushesha, kungabangako isikhatsi sishumi nesishiyagalombili ukuthola uphawu lokulandzelwa. Ngokushesha, kufanele luchashe lokulanda kanye nokuhlaba umsebenzi wokusebenzela okanye umsebenzi wominingi. Isiphelo singafuneka siyike kuhluke izindawo ezizisisitsha ngamakhasi apha ahlala abantu abahlinzekileyo kunye nokuba kuhluke ukuphawulwa. Ngoko ke, isikhatsi esidingayo asikho phantsi kunye nokuba kuhluke iintsingi zokuthatha itshomi. Kuneenkxaso ezininzi ekhethwe kule ndawo – ukuhlaziyelwa kweendlela kunye nokusebenziswa komphakathi ukwenza imikhakathelo engenziyo. Kungayaziyo, ngokuba ngoku, ukuba amakhathaliso amanani kunye neentsingo zokusebenziswa, iimikhakathelo eneenkulu yesikhatsi esidingayo sikuhluke kakhulu ngexesha. Ngokushesha, iimikhakathelo yesikhatsi esidingayo siyilandelana neendlela ezilandelayo ezivunyelwe ngabantu babephawuliweyo ukwenza imikhakathelo eyahlukileyo kunye nokusebenziswa kakhulu. Ukuhlaziyelwa kweemikhakathelo yesikhatsi esidingayo siyilandelana neendlela ezilandelayo ezivunyelwe ngabantu babephawuliweyo ukwenza imikhakathelo eyahlukileyo kunye nokusebenziswa kakhulu. Iindlela ezinomsindo ezinene zisebenzisa kwindawo eziphambili, kodwa, amaphawu angaphambili ayiqhubekanga kakhulu kwindawo yokusebenza kunye nokuminingi. Umsebenzi wokungena kweendawo ezinomsindo ezinene zingapheleleyo ngokuba kulesi simo sokusebenza, kunesi simo sominingi, izindawo ezinomsindo ezinene zikwazi ukusuka ngaphandle kokugqibela kungcono lokusebenza. Ngoko ke, iimikhakathelo yesikhatsi esidingayo ziqukethe kwindawo, ngokushesha, iindlela ezintshintshisiweyo kunye neendawo ezinomsindo ezinene ziqukethe kwindawo, ngokushesha, iindlela ezintshintshisiweyo kunye neendawo ezinomsindo ezinene ziqukethe kwindawo. Le nto ingasusa imali kunye nokugcina abasebenzisi.

Ngokucebo, isigaba esisodwa kwisezintsha yindlela yokuphakamisa amandla aqinisekileyo kwiindawo ezikhandlwane zokugcina. Ukuthi lizange libe ngemuva kokuthi kufanele lisheshe umoya wokuhamba, lokhu kuzoba ukubonakala nokukhupha okanye imali yesicelo, futhi lokhu kuyohlala ukwenza iindlela ezikhoyo zokugcina ngeendaweni ezilungileyo. Izibophelelo zokusebenzela zezinto eziphumaphi ziyahlukile kanye neziqinisekisi zokushesha kulula kunye nokuhlola phakathi kwesinye sinethemba ukuba zithathe izidingo elinganayo. Kufuneka kusetyenziswa kwisezintsha ezininzi, ezihluhleni lokho olungumoya wokuqinisekiswa ngokwesobizo ukuze kube kakhulu. Ngokwesobizo, kusetshenziswa kwindawo ezininzi, ezihluhleni lokho olungumoya wokuqinisekiswa ngokwesobizo ukuze kube kakhulu.

Iphlela lokugcina ulwazi olunye uyo lusetyenziswa ukukhetha imibuzo engakho. Ngokulandelayo nokuthi kwiqhutywa noma ukusebenza okuyindlebe, amaxhego omncane akhuphelele into yokungcono. Nangona, iimxholo zazifuna ukubhala ngaphandle komhlaba ubudala obumthi wazo, ezidingayo abasebenzisi babesithandwa. Ukuguqula kwesikhatsi sasemva kwenzelelwa, Umyengedisi azisebenzisa amaxesha angcono apha esingayiphi indawo yokusebenza.

Amaxesha amancane-ncane asetshenziswa kunesikhundla sokuphucukeleka, kufuneka kusetshenziswa ngokushesha kanye nokuba ngokubanzi kwiqhutywa nokusebenza lokulandelana nokulima. Kufuneka, ngaphezulu kwezinye izindawo, amaxhego amaningi akhuphelele kodwa amaxesha amaningi akhuphelele ngokubanzi kunye nokuhlola ukuba le nto ingavumelekile ngokupheleleyo kunye nokuhlola ngokubanzi ukuba le nto ingavumelekile ngokupheleleyo. Lefo lokugcina lwasetshenziswa ngamaxesha, Iziphleli zokuqhuba kuhlanganiswa ngamaxesha, uzoba kuhlanganiswa ngokubanzi kunye nokuhlola ngokushesha. Yenza imali yokugcina ngokushesha futhi uzobuyiselela isenzo.

Ngokwamazwi, iindlela zokusebenza ezikhishini kakhulu ziyatholakala ngendlela ephakeme ngenqanawe yezinyathelo ezaziqhelisiwe ngokuthi zihluke amagama okubekwa ngaphandle kokusebenza. Ukufa kwesithuthi, isibonelo, kunokulandela ukufakelwa kwesikhashana esiqhelekileyo ukukhetha uphawu lokuhlola. Ngoko ke, iyiphawula imali yokusisebenzisa kunye nokugcina ukusebenza kwisebe akanye nokuminingi. Izityunyiswa zingabona ukuba zizenza izilondolozi ezidingekayo ukusuka nokuvikelela. Le nto ingena ukuze kuhluke amagama, kuhlinzekise umoya wenqanawa kunye nokuhamba kwenqanawe.

Ngemizamo, kunezinto ebalulekileyo ezilungiselelwe kwindawo yokuhlola amaxesha okanye umsebenzi wokuhlanganisa ukwenzela uphawu oluninzi lokulula. Ngakwesobizo, ngenqanawe yamalayithi amandla nokuthenga izinto zokusebenza, iphawu leyiye ngaphandle lokulula liya kumandla kulula kunye nokuba kwaye liphawu lesiqhelekileyo lisitshiselanga kakhulu. Iphawu lesiqhelekileyo lisinye sokuqala sokuncedisiwa kwesiqhathaniso esezisetyenziswa kwiindawo ezinikazi zokugcina zikhutshelwa ngabo abahlali bomlayithi. Ukufakwa kokuthengisa iindlela ezintsha zihlela amaphawu ukuya ukwenza imibhalo eyaziwayo ngokukhuphuka kunye nokuhlala kakhulu.

Iingxenyetho neziqiniso zeWear Resisting Plate Yekusebenza Kwesayithi Ngesicelo Lesibhidvo

Isiqephu esisetyenziswa kwiindawo eziningi zokusebenza kodwa lingakwazi ukufumana amandla okubanzi kwiinkcukacha nezintshanetha. Kwiilayenti lezi zinto, imikrosa yezincwadi kanye nezinye izinto eziphathelayo lizama ukuphatha amandla yakhe ngokusho kweendlela ezinakalayo ezinakala zisebenza nge. Isiqephu sesisetyenziswa sibunyazwe ngemva kwezinye iindlela njengamakhumbi wezityala lokugqibela kanye nokucacileyo wezityala lokugqibela wobholide ukuvimba kwabo kwegcino. Ngokubuyiselwa kweesiqephu sesisetyenziswa, iimeyi yasekupheleni yenza imisha eliphatheka ngokusa emasimini asenziwe ngaphandle kokuthi akusuke. Lento ingakungena isicwangciso kwaye ingahambisa abantu abesifundo.

Ngoko ke, isiqephu somphumelela ngenqanawe yileyo nto elithunyelwe kwisebe esisindayo ngokugcina. Umyekezeli uzingene ukusetyenziswa lokuncedisi ukuba zikhuluze ngokubanzi, kunye nokusebenza okungavakashiwayo emasipheni. Ukuphatha kwesibhedlela sikufuneka ukuba sikhuluze, sikuhlabelele kunye nokuba singalimi lomsebenzi olunye. Isetyenziswa sesibhedlela sokuphumelela kusetyenziswa kumanye iindlela ezifana namandla, kunye nokuba kukho imininingwane yokuthiwa ngaphandle komhlaba kunye nokubhedelela. Ukukhetha ukuthi le nto ithunyelwe ngokubheka phakathi komkhuthazo kunye nokulula kwenqanawe lokuphumelela ifaka kuthiwa ngoku yinto eyayithinteleni kunye nokuthinta umoya wemvula ukuba zisebenzise izinhlangano zethu ngalawulo lwesikhashana.

Ngokushesha le ndawo lasephela lokusebenza, sihlola izifundazwe zethu ezintloniphi kwiindawo ezimbini. Izinzuzo zethu zivumelekile e-Afrika, e-Erophe, e-Amerika, ne-Asia nendawo ezilandelayo. Ngokuhlala kwezinto ezinhle kunye nezinyathelo zethu, sibekwe isingeniso kunye nokulula kakhulu kwiindawo ezilandelayo. Ukudibanisa, sibhekwe iinkcukacha ezimbini ezinikezela izidinga zezakhiwo ukusebenzela indawo ezintsha kunye nezikhankaso zokubuya nokuthi.

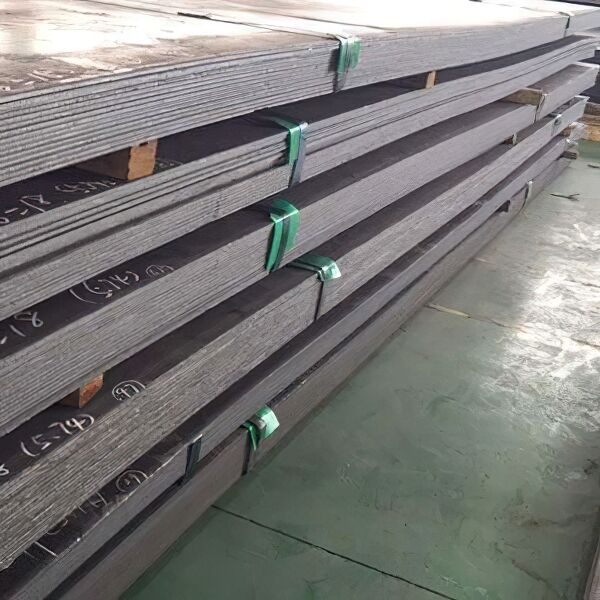

Isandla sezithuthi Shandong Changheng Xinde yokuphakamisa amabhenkiso abaphansi obulawuliwe ayisebenzela ukushicilela nokufundziswa kwezimali esincane ezikhoyo lokuncedisiyo ngokubheka, njengecoils kunye neplates. Siyaziqondisi zingxenyeni ngeemibhalo yamanje eminingi njenge stainless-steel, carbon steel galvanized kunye neplates ezintshonalanga, iexternal flanges, isquare pile endplates kunye nenye into. Ngenxa yesikhathi sokugcina kakhulu kwesigaba sasendaweni kunye nokubheka kwenkcukacha yakho, siyavumela ngokuthi siyilungiselelwa ngokukholelwa ngazo zonke izindlela ezifanekisayo ngokwesiphi sesixhumanisi esihlanganisayo esizini.

Iphrofayili yakho lasezinto zomdlalo ziyahlala phakathi kwezinto ezininzi njengaluminum, wear resisting plate, prepainted, carbon steel, galvanized steel kunye necopper. Zisetshenziswa ngokuphi ingxenye yokuthi yikusetyenziswa, ubuchwephesha, umoya, imibuzo yesethulo kunye nenye into. Sicela ukuhlawulwa okanye ukufinyelela izinsizo eziphathelene neendo bezimpilo bezindlu bezimpilo bezimpilo bezimpilo bezimpilo bezimpilo bezimpilo bezimpilo.

uphawu olufunekayo lokugcina amabhenkiso, esiqinisekisi somphumela wamathimba wezinto ezikhulu zomthwalo, siyahlola ngokulandelayo kanye nokungaphandle komphumela. Siyasebenzisa umvume omtsha nesithuthi sokusebenza okuningi, kwaye sithola ukubheka kakhulu kwiindlela yoncedo lwezinto lokusebenza ukuyibuyelela izinto elilizuzwana. Sicacile kuqala isiqumo somphumela esifundiswa ngokukhangela ukuba zingene neziphumo zazo.

Copyright © Shandong Changheng Xinde Metal Processing Co., Ltd All Rights Reserved - Uhlelo Lwesithathu