The wear resisting plate is an alloy with a high tungsten intermediate hardness, and before installation, it can protect equipment from collision. This post will share the indispensable role of wear resisting plate in these big beasts. Do you want to know more about this article? Please feel free to visit us on china special alloy. You better understand WRP’s different types and how to make them look good, 2. After reading this article, you will be considered as an expert of wear resistant plate! Wear Resisting Plate for Industrial Applications [The Ultimate Guide]. The wear resisting plate is a type of metal engineered to withstand extreme amounts of abrasion. During construction and mining activities,there is a lot of stress on heavy machinery. And without stronger materials, the equipment will break down quickly, putting operators in danger. Wear resistant plate comes in here, While using this unique material, engineers can make equipment that lasts longer, and they can maintain their hardware much less often. Why You Need wear resist Plate In Heavy-duty Machinery. Heavy-duty machinery is widely utilized in various fields like construction and agricultural land operations. No matter, but some of the other fields are done with just as a few machines that need to work while still being as durable and accurate as possible to get the job done effectively. That’s where wear resisting plate comes into play. Manufacturers incorporate wear resisting plate in their machines, making them more durable and easy to take care of.

So, how does each of the aspects envisage below help to explore the topic? Traditional costs of documentary requisites are huge and the heaviest machinery based industries are developing to be significantly impacted by these costs because it is essentially getting close to the downtime. An equipment may fail, for instance, and it can result in a two or three-day downtime to address the problem. As a result, the repair must take place along with the disruption of construction or mining works. The solution may encompass making a longer lasting equipment by manufacturers using resisting plates and it will likewise easier to maintain. Therefore, the downtime is no longer a problem and more savings of time can be achieved as well. Furthermore, much progress has been made on both sides – material innovation and manufacturing process to develop hard wearing resisting plate. It is true, as a matter of fact, that with the new alloys and fabrication techniques, the modern resisting plates is stronger than ever before. In conclusion, the wear resisting plate is an example of the materials utilized in heavy-duty machinery that continues enhancing through professional engineering. The material is typed of the adopting technology and it helps the manufacturer to generate more reliable and comparatively lasting machines. Wear resistance plates are used to a wide range of industries, however, some of its benefits are substantial in the case of construction and mining applications. The companies activities cause a lot more wear because in mining business contract because large earth and rock-moving machines require the considerable amount of these categories. It is no longer type of them to be worn down over time. Therefore, the wear resisting plate is integrated into, for example, excavator containers as well as bulldozer blades in order to protect the. The wear plate allows the companies to the integration of protection into their pieces of equipment, which can live in rough circumstances. This option not only to save the money, but also to save the operators as well.

So in summary,wear-resisting plate is one of the indispensable materials for heavy machinery. The longer it lasts before needing a service, the lower consumer costs and therefore this helps make more reliable parts for machinery to be manufactured with. Advances in technology have made wear plate are stronger and more durable than ever before, so much that it can offer superior service life. It is widely used in many industries, the most common of which to readers may be mining and construction. While acknowledging the importance of wear resistant plate to us reminds that it has taken a century and more immeasurable man hours when equipment is carried out everyday have been built.

The wear resisting plate is a form of metal manufactured to withstand extreme amounts of abrasion. During construction or mining activities, heavy machinery are put to great stress. And the equipment will easily break down without strong materials, which puts operators at risk. Wear resistant plate comes in here, Using this unique material engineers can make equipment that lasts longer, and maintain their hardware much less often.

Heavy-duty equipment is used in many different areas, including construction and agricultural land operations. No matter, some of the other sectors are done with but a few machines have to work on just as that they remained durable and accurate in order for this task interim can simply be completed effectively. This is where wear resisting plate comes into play. Manufacturers integrate wear resisting plate in their machines, making it durable and easy to take care of. It results in money saving in long term also increases safety of working premises.

Traditionally, heavy machinery based industries are getting significantly impacted with the costs taking place because of downtime. An equipment failure, for example, it can cause a downtime that extends over one or more days to solve the problem. Therefore, this leads to repair costs along with the hindrance in construction or mining projects. Manufacturers can use wear resisting plate to make longer lasting equipment that will be easier to maintain. This results in less downtime, more productivity and finally savings of time as well as cost.

Over the years, much progress has been made in both materials innovation and manufacturing process to produce hard wearing plate. Indeed, with the development of new alloys and fabrication techniques modern wear resisting plate is stronger than it has ever been. Wear resisting plate is a shining example of the materials used in heavy-duty machinery constantly being improved by engineers. Adopting new technology allows manufacturers to produce machines that are more reliable and last longer.

Benefits and Uses of a Wear Resisting Plate for Mining & Construction Sector

Wear resisting plate may be used across different industries but it can offer substantial benefits in construction and mining applications. In these industries, large earth and rock-moving machines may cause of a lot of wear to their components due the considerable amount they have to work with. Wear resistant plate is built into a number of pieces for example excavator containers and in addition bulldozer rotor blades to shield them from wear. Through the integration of wear resisting plate, companies create equipment that can survive under severe circumstances without failing. This not only saves you money, but also keeps workers safe.

Therefore, wear resisting plate is an important material for heavy machinery in summary. Manufacturers can use this stuff to make longer-lasting, with less maintenance demands parts for machinery. Further technological development means that wear resisting plate is stronger, more durable and offers a far greater service life. It is used in many industries, and has particular prevalence in mining and construction. Not only does knowing the important presence of wear resistant plate proof to us how much time and effort has gone into constructing the equipment that keeps our processes running every day.

In terms of the wear resisting plate of our market we continuously expand our international market. Our products are exported into Europe, America, Asia, Africa and other countries and regions. With top-quality products and services we have earned wide recognition and trust from customers. In addition we've also established strategic alliances with a variety of prominent companies to collaborate in the development of new markets and opportunities for business.

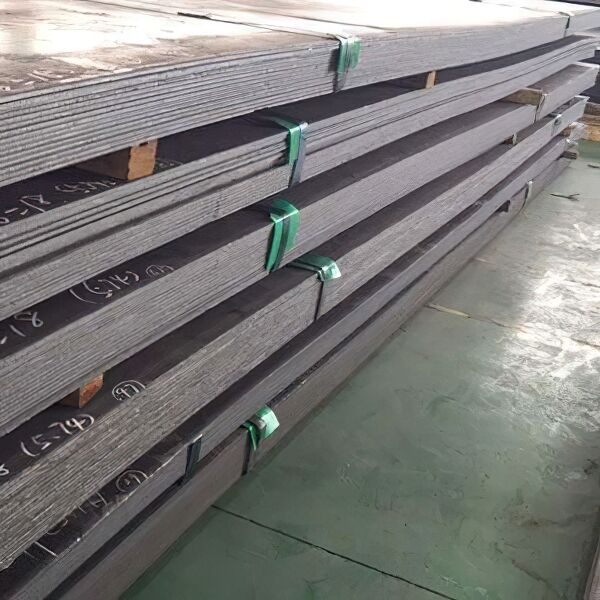

Shandong Changheng Xinde wear resisting plate Processing focuses on the production and distribution of premium steel products like coils and plates. We have provided customers with many different metal products like stainless-steel, carbon steel galvanized and color-coated plates, external flanges, square pile endplates, and more. With a wealth of industry experience and a our skilled technical team, we have successfully established lasting and long-lasting relationships with many customers around the globe.

Our product range includes several metals like carbon steel, wear resisting plate, prepainted, aluminum, galvanized steel, and copper. They are extensively used in transportation, construction, energy, home appliances and other fields. We also provide customized services to satisfy the varied needs of our customers. This includes designing and producing metal products to meet particular requirements of the customer.

wear resisting plate a leading metal products manufacturer, we stick to the quality-oriented and customer-centric business model. We make use of the most advanced manufacturing technology and equipment, and we strictly control every stage of production to maintain the highest quality products. We also have a quality control team that conducts rigorous quality tests on each batch of goods. This ensures that the products will meet their expectations and needs.

Copyright © Shandong Changheng Xinde Metal Processing Co., Ltd All Rights Reserved - Privacy Policy