A cold rolled steel sheet is not terribly glossy; that puts it on its own wavelength in terms of metallic materials, which has certain advantages and uses all on its lonesome with regards to construction and manufacturing. To give you a true understanding of the value in this material, we will introduce its qualities as well as where are good to use and how though it might be for manufacture; while on other point there intended application is galvanized GI Sheet advantageous construction or generalfications project recommendations choosing type with right property Titans only choice & when theyt crackps pressing criteria get about 5 spread everything pop up coming too illtypeofsheetmedal sheets.

Using cold rolled steel sheet has numerous benefits. One thing is for sure - this metal sheet lives the longest. All these tough properties make it perfect for many uses in the construction and manufacturing industry. In addition, bronze is also easy to weld and shape that make it more desirable for different types of moulding or building designs. The cold rolled steel sheet has many important characteristics and this is one of the reasons it still occupies a significant place in so crucial segments like automotive industry, fast glass buildings construction or furniture building.

Most Difficult Technology of Production for Cold Rolled Steel Sheet

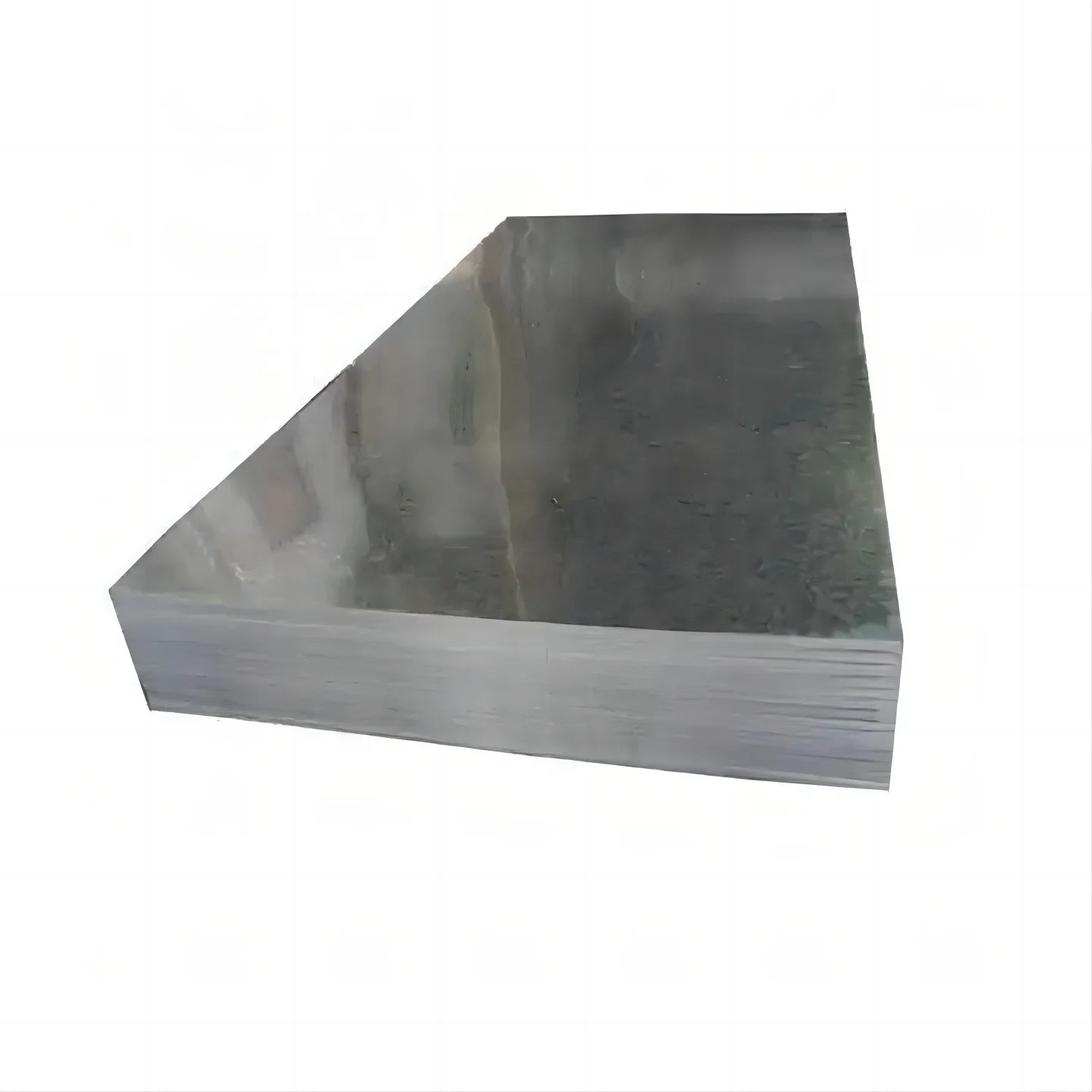

Cold Rolled Steel Sheet is the name given to a series of sheets produced in this manner where each has been rolled below its base or room temperature. This makes the sheet more tough and long-lasting. This material is rolled up to the final size using a cold-rolling process by passing it through rollers under an applied pressure. Finally, the sheet is annealed to increase its strength and ductility.

The strongest of these properties is the cold rolled steel sheet. The way it stands up to harmful weather conditions makes it perfect for any construction-related work. And it is very resistant to corrosion which makes for great use in humid and moist zones.

A key advantage of cold rolled steel sheet is that it can be processed into a mixed shape. Strength-to-weight ratio isn't as good for steel, but it's easier to form and weld so that you can get more creative with your design structures. Its flexibility has seen it become a common option across various sectors, from car production to construction and creating furniture.

ConclusionAfter introducing the above points, I bet that you are required to take more consideration before buying cold rolled steel sheet. Number of these are available in the market with their own features and functionality, so it is also very crucial that you stably choose things for your project. When it comes to making the final decision size, weight and (to a certain extent) quality -- all things that can be variable -- are factors you might wish to take into account.

And if we do a comparative study, the cold rolled steel sheet stands out from other metal sheets due to its many ergonomic factors. With stronger and abrasion-resistant properties compared to hot rolled steel sheet, this product is used for building or manufacturing requirements since it may finish all possible nature conditions. Better yet, it is also corrosion resistant and ideal to be used in a moisture laden environment.

In the end, it is what makes cold rolled sheet metal as a building material that truly shines; because of its flexibility and timelessness in construction practices relevant to manufacturing. Knowing the basics details of why bamboo is in now a days and its production process as well how to choose this material right the first time allowing you to enjoy all that presented by it. When compared to many other metal sheets; cold rolled steel sheet has established itself, Hence the raw and an adaptive counterpart makes it a good usage in numbers of projects.

With regard to the development of markets we are constantly expanding the international market. In addition, our products are sold into Europe, America, Asia, cold rolled steel sheet and other countries and regions. With our high-quality services and products We have received widespread recognition and trust from customers. At the same time we've also established strategic alliances with a variety of known companies to create new markets and business opportunities.

As a professional metal products manufacturer, we adhere to the cold rolled steel sheet and quality-focused business strategy. We make use of the most advanced manufacturing technology and equipment. We also monitor every step of the production to ensure that we are producing the best quality products. We also have a quality-control team that performs thorough inspections of every batch of product. The team ensures that the products will satisfy their requirements and expectations.

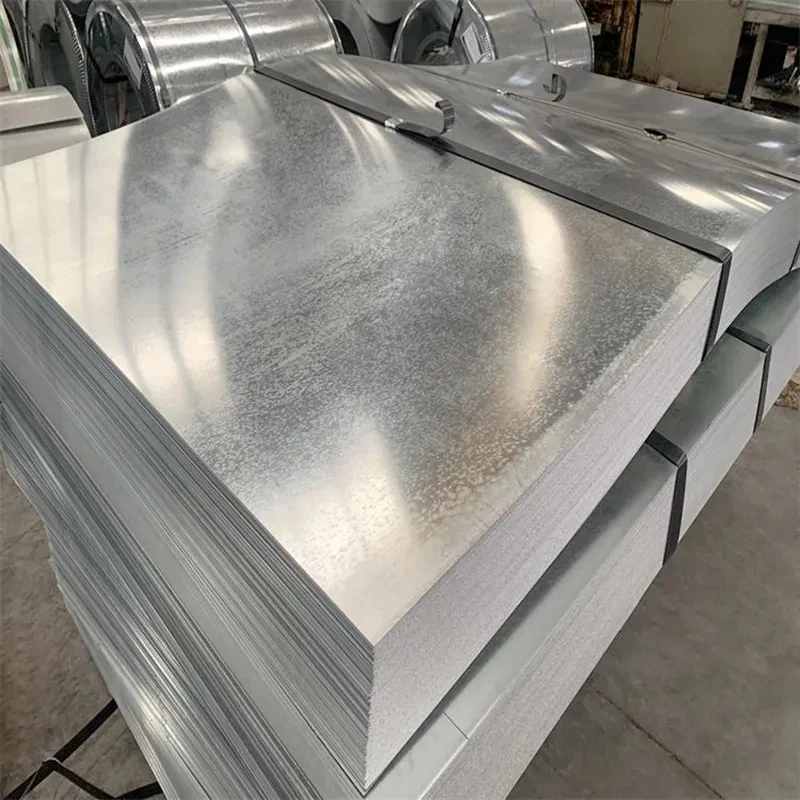

Our product range includes several metals like carbon steel, stainless, prepainted, aluminum, galvanized and copper. These products are used widely in the cold rolled steel sheet, transport, and energy industries, and also in home appliances. We also provide custom-designed services to meet the various demands of our customers. This includes designing and manufacturing metal products based on the specific requirements of our customers.

Shandong Changheng Xinde Metal Processing focuses on the production and distribution of premium steel products such as plates and cold rolled steel sheet. Over over the years, we've been devoted to providing our customers with the highest-quality cold rolled steel sheet, galvanized, color-coated external flanges, end plates with square piles, as well as various other products made of metal. We have established stable and long-term relationships with our customers from all over the world, thanks to our extensive industry knowledge and technical team.

Copyright © Shandong Changheng Xinde Metal Processing Co., Ltd All Rights Reserved - Privacy Policy