Steel, one of the most important elements in many industries, is widely used for building homes and heavy machinery alike. Of all the acquired hands of steel this is one hand that stands taller, when compared to every other type available; and yes I am referring cold rolled steel coil.

Cold rolled steel coil is created by passing hot-rolled through a roller at room temperature. As a consequence, rolled-on steel is both stronger and has higher warp-strength, but also exhibits superior surface smoothness.

Cold Rolled Steel Coil has several advantages in the context of industrial manufacturing. The first of which is that since it grows much stronger than before, you can use it for load-bearing structures and machinery. Moreover, it is relatively low carbon allows better welding and forming capabilities.

One other benefit to the cold rolled steel coil is how much better it looks than its hot-rolled competition. This smoothness of the product allows for it to be a more visually appealing alternative and is less likely too corrode, making it ideal architectural use such as handrails that need this premium finish.

Cold rolled steel coil production is a cost-effective process that maximizes efficiencies during the manufacture. This process of passing hot-rolled steel through rollers at room temperature results in a slightly tougher and more durable product.

One of the main methods by which costs are significantly reduced in cold rolled steel coil production is through recycling of used or scrap steel. This said by recycling the scrap metal, it means that less demand on new raw materials when increase lower production cost branches.

The automation and use of advanced technology in the production process enhances efficiency and significantly brings down expenditure on labor. There are also machinery and robotics that follow a computer controlled design to ensure accuracy in the manufacturing process.

Competition means greater sales, which will lead to higher profit as well but the global market for cold rolled steel coil is certainly no slouch with loads of suppliers and distributors being tasked that couold cater top demands within such an industry segment. Key players operating in this market segment include Arcelor Mittal, Nippon Steel Corporation, JFE Steel Corporation and Posco.

Arcelor Mittal, one of the leading steel manufacturers in the world obviously provides a wide range of cold rolled coils for various industrial and commercial applications. Nippon Steel Corporation is one the largest and renowned manufacturer of high quality cold rolled steel along with other type of steels. JFE Steel Corporation is renowned for its cold rolled high strength, high durability products. POSCO, the largest steel provider in Asia offers a wide range of Cold Rolled Steel to like that are used for Industrial Purposes.

The cold rolled steel coil has excellent properties and can be widely used in the fields of automobile manufacture, construction, transportation and household appliances.

Cold rolled steel is a large class of automobile industry used for manufacturing everything such as body panels, chassis and suspension parts. There are many things that comes up by using cold rolled steel in automotive components like improved strength, light weight component and this has a significant benefit to improve fuel economy.

Cold rolled steel is commonly used within the construction industry to make a range of components, including wall systems, roofing material and structural framing. Cold rolled steel for construction boasts a range of benefits - from increased strength and corrosion resistance, to greater design freedom.

These advances relate both to the production and surface treatment of cold rolled steel coil. Innovation in this area includes the manufacture of custom high-performance alloys for specific properties like strength.

A second area of innovation relates to how surfaces are treated, using processes such as cold galvanizing or painting and powder coating that can enhance the corrosion resistance properties when taking into account various steel qualities.

To sum up, cold rolled steel coil has many advantages in industrial manufacturing and construction. Thanks to a steady stream of innovation and continuous process improvements designing the future using material technology, Steel will continue its ubiquitous presence across several industries.

As a cold rolled steel coil metal product manufacturer, we always adhere to a quality-oriented and customer-focused business model. In the production process we utilize the most modern production equipment and technology and rigorously control every production link to ensure that the quality of our products are always at the top of the market. Additionally, we have a qualified quality inspection team that conducts rigorous quality inspections of each batch of product to ensure that the items delivered to customers meet their expectations and requirements.

Shandong Changheng cold rolled steel coil Metal Processing is a company focused on the manufacture and sale of high-quality metal products, including steel plates and coils. Through over the years, we've been committed to providing our customers with the highest-quality carbon steel stainless steel, galvanized, color coated external flanges, end plates for square piles and various other products made of metal. We have established solid and long-term partnerships with customers across the world thanks to our vast industry experience and technical team.

We continuously expand our global market, and we export our goods tocold rolled steel coil, America and Asia in addition to Africa and other areas. We have earned the trust of our clients by offering high-quality services and products. At the same time, we have also established strategic partnerships with many famous companies to develop new markets and opportunities for business.

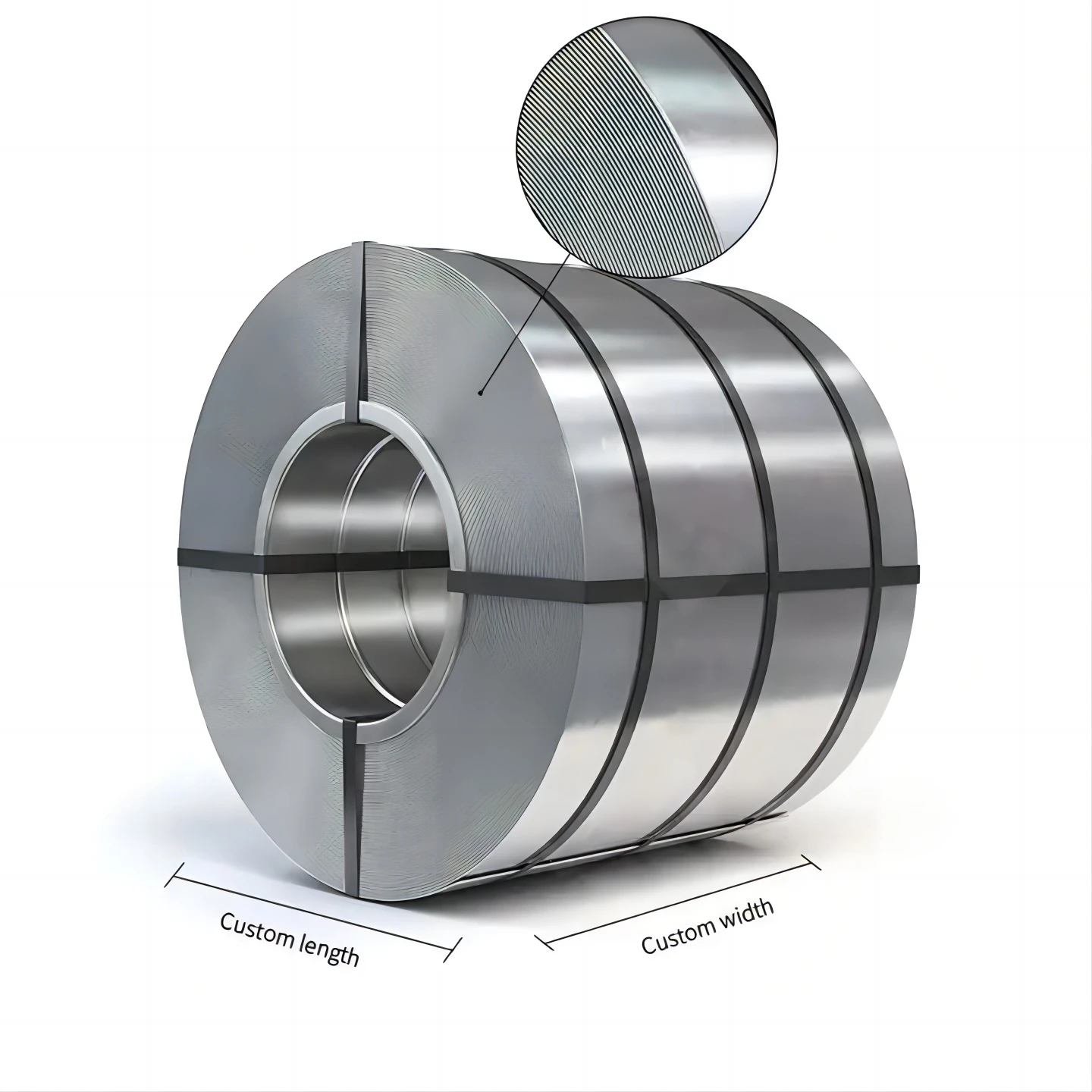

Our product line includes many types of metal products which include carbon steel, stainless steel galvanized, prepainted aluminum and cold rolled steel coil, among others. They are extensively used in the fields of construction, transportation and energy, as well as appliances for homes and in other areas. To meet the demands of our customers, we offer customized services, making and designing metal products that meet specific specifications according to the specific requirements of the customers.

Copyright © Shandong Changheng Xinde Metal Processing Co., Ltd All Rights Reserved - Privacy Policy